Scientific news ticker march 2021

Reactive disruption management for the assembly of low-volume, complex products

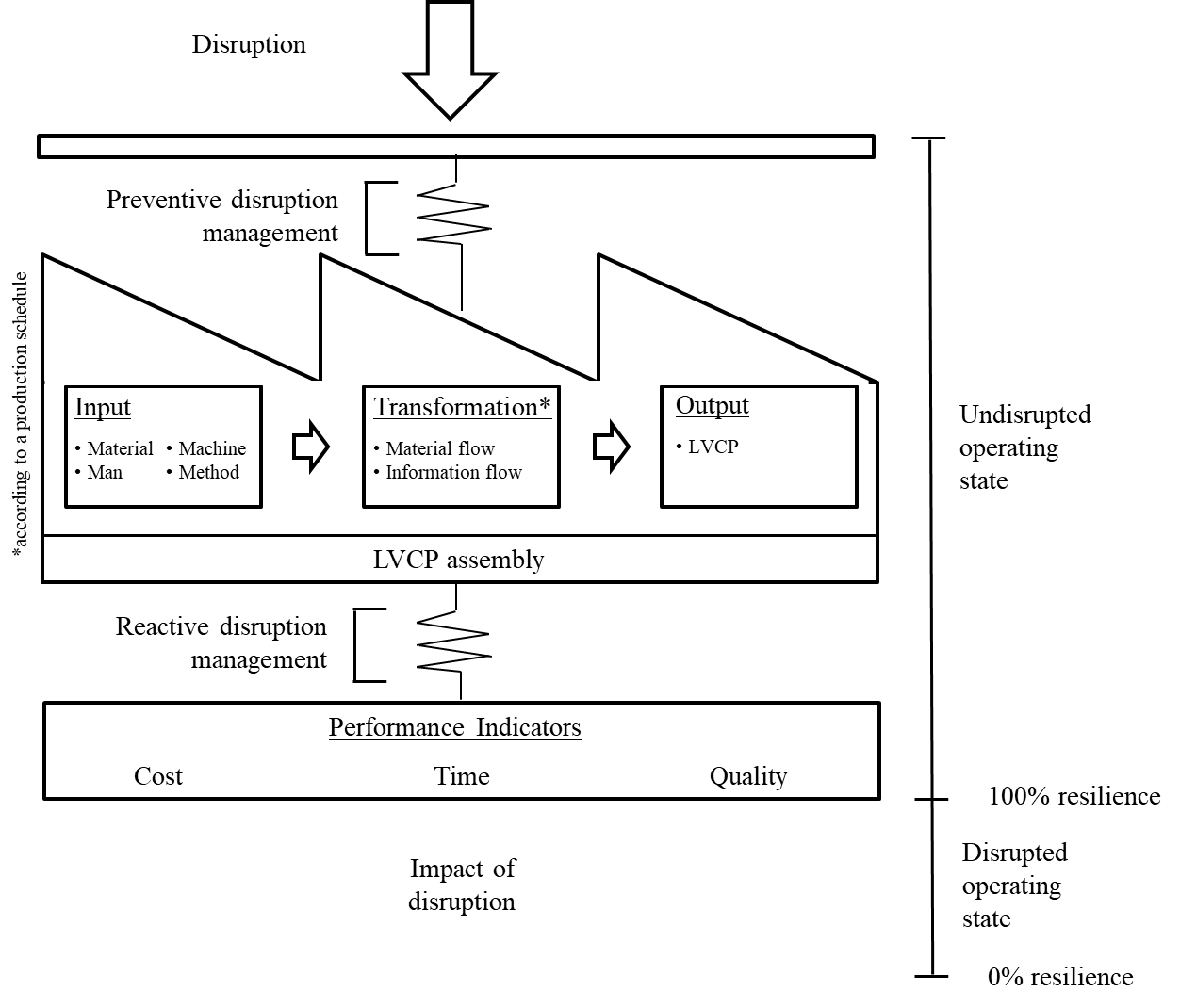

The assembly process of most low-volume, complex products (LVCP) is compromised by disruptions. Disruptions cause deviations from the planned assembly schedule, which harm the economic performance of LVCP manufacturers. LVCP such as passenger planes, trains, and medical machinery form an important group of capital goods across various industries, e.g. aerospace and transportation. Due to the high value of LVCP, disruption can lead to significant financial implications. In order to minimise the negative effects of disruptions, most companies deploy disruption management. Our observations, made in a single case study, imply that disruption management in LVCP assembly differs from other manufacturing environments. Reasons are for example the manual disruption detection, the technical complexity of the products and legal obligations towards manufacturing process adherence.

Picture: The effects of disruption management design on manufacturing systems

The scientific literature on disruption management in manufacturing puts little emphasis on the assembly of LVCP apart from few exceptions, e.g. (Burggräf et al. 2017, p. 332). Most studies reviewed are situated in machine-based manufacturing environments and invest limited effort to elaborate on the general mechanisms of disruption management. Furthermore, the studies reviewed tend to neglect aspects such as disruption data collection methods, and disruption attributes recorded. Nonetheless, it is stressed that collecting disruption data is key for effective disruption management (Zou et al. 2016, p. 260).

This research addresses the illustrated research gap in three independent studies which form a cumulative PhD-thesis. The guiding and overarching research question is: “How do disruption data collection methods, recorded disruption attributes, and disruption management routines contribute to an effective reactive disruption management in the assembly of LVCP?” We found this research on two theoretical pillars. We draw inspiration from the Normal Accident Theory which implies that disruption will occur at some point in complex and tightly coupled systems such as manufacturing systems for LVCP (Perrow 1981, p. 17). Thus, LVCP manufacturers require routines to minimise their negative effects. Furthermore, we aim to apply the Transaction Cost Theory by modelling disruption management routines as transactions within LVCP manufacturers. Using this model, we will develop an in-depth understanding of the cause-and-effect-relationships within disruption detection, disruption response routines, and disruption measures.

In order to pursuit this research question, we gather qualitative and quantitative data from three distinct methods. Firstly, we deploy structured literature reviews on low-volume complex product assembly, disruption data collection and disruption management routines. Secondly, we plan a multiple case study taken from a representative sample of European LVCP manufacturers where we conduct interviews and examine data on disruptions. Finally, we prepare time studies at a LVCP manufacturer in a single case study, which allows us to measure the performance of disruption management routines before and after we introduce changes to these routines. For the design of our case studies we follow the suggestions by Eisenhardt and Graebner (2007) (Eisenhardt and Graebner 2007, p. 27). Merging these research methods enables us to display the similarities and discrepancies between the scientific literature and the field, and to generate new theory on this research topic, which is rather unchartered territory in the scientific literature.

Ansprechpartner: Stephan Breiter, Julia Arlinghaus

Publication bibliography

Burggräf, Peter; Wagner, Johannes; Lück, Katrin; Adlon, Tobias (2017): Cost-benefit analysis for disruption prevention in low-volume assembly. In Production Engineering 11 (3), pp. 331–342.

Eisenhardt, Kathleen M.; Graebner, Melissa E. (2007): Theory building from cases. Opportunities and challenges. In Academy of management journal 50 (1), pp. 25–32.

Perrow, Charles (1981): Normal accident at three mile island. In Society 18 (5), pp. 17–26.

Zou, Jing; Chang, Qing; Lei, Yong; Arinez, Jorge (2016): Production system performance identification using sensor data. In IEEE Transactions on Systems, Man, and Cybernetics: Systems 48 (2), pp. 255–264.